As an HVAC installer, you have to be a Jack (or Jill) -of-all-trades with a working understanding of many aspects of the construction industry. Will you soon have to add 3D printing to your list of skills?

As an HVAC installer, you have to be a Jack (or Jill) -of-all-trades with a working understanding of many aspects of the construction industry. Will you soon have to add 3D printing to your list of skills?

Unless you’re doing custom projects with massive budgets, you probably don’t have to worry. 3D printing technology is still expensive, and high-quality affordable HVAC components such as ducts, vents and heating and cooling systems are readily available from manufacturers who are producing tested designs. Where the HVAC industry will benefit from 3D printing is in design innovation.

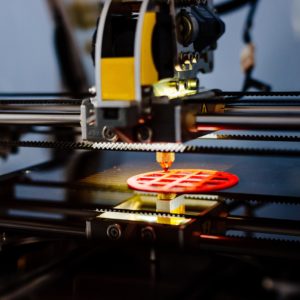

3D printing is a process in which thousands of layers of a material are used to form a 3-dimensional object. It is also called additive manufacturing, and the materials that can be used in this process include polymers, metals, alloys, cement, and even some kinds of food.

The process begins with design software. Once the 3-dimensional design is complete, it’s translated into instructions that are sent to a 3D printer. It layers material to print out the object.

The process has been around since the 1980s and was used primarily for rapid prototyping. Along with the development of 3D printing for personal use, commercial applications are finding uses for it as well.

How 3D printing provides choices

For HVAC this may mean improved products. The University of Maryland, with its partners 3D Systems and the US Department of Energy, has designed a prototype heat exchanger that is 20% lighter and 20% more efficient than the heat exchangers currently in use.

Many different types of heat exchangers are used in HVAC and other industries; they are all comprised of chambers or channels through which air, liquid or gas of varying temperatures will pass, with the temperatures of each channel impacting the other. They can be used for both heating and cooling purposes.

The Maryland heat exchanger is for air conditioners. Because 3D printing is made up of microscopic layers, the design for the heat exchanger can include 200 micrometer thin walls that are still able to withstand an immense amount of pressure. This makes it both lighter and more efficient, and it may broaden the range of materials that could be used to make heat exchangers.

Most heat exchangers are made of metal because metal is strong and very conductive which facilitates heat transfer. But conductivity is not the only factor in heat exchange. Surface area facilitates heat exchange as well, and a design that features 200-micrometer walls and a bigger surface-to-volume ratio may not require the added benefit of conductivity.

Plastics work well for components such as wall caps and soffit vents. Along with other new materials made possible with 3D printing, this might revolutionize the manufacturing of cooling and heating systems.

The 3D-printed heat exchanger is built with a continuous printing process that makes one solid object with no seams that will not leak. This extends the life of the heat exchanger as well as all of the other parts of the air conditioner. It also decreases the potential for fouling. Fouling occurs when some outside material creates deposits in the pathways of the heat exchanger and disrupts the flow of air or liquids.

The 3D-printed heat exchanger developed by Maryland University is expected to be market-ready in four years, and other 3D-printed innovations are sure to be announced in the meantime!