Your customers want to reduce their energy bills. For owners and operators of large residential and commercial buildings, variable refrigerant flow (VRF) HVAC could be the way to go.

Your customers want to reduce their energy bills. For owners and operators of large residential and commercial buildings, variable refrigerant flow (VRF) HVAC could be the way to go.

The benefits of VRF include energy efficiency, improved comfort and integration with smart technology, but it’s not ideal for every project. In contrast to air conditioning only systems, VRF systems provide both heating and cooling but they do not provide ventilation, and installation requires special training.

What is VRF?

Variable Refrigerant Flow (VRF) systems were developed in Japan more than 30 years ago, and they are becoming more popular in North America.

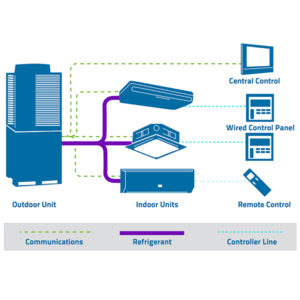

VRFs are similar to the ductless multi-split HVAC systems used in smaller buildings, but they are more complex, and they use only refrigerant for cooling. The system is made up of a large outdoor unit that houses one or more compressors. The outdoor unit sends refrigerant to smaller evaporator units inside the building.

The outdoor unit can support multiple indoor units with varied capacities. The result is variation in the heating or cooling that can be controlled by each unit. VRFs are often ductless, but they are sometimes set up as a duct system.

There are three different VRF types:

1. Cooling only systems

2. Heating Pump systems: the condenser unit cools and heats, but it can only do one of these at a time.

3. Heat Recovery systems: they can deliver heating and cooling simultaneously to different units.

The benefits of VRF

With VRF, the residents of a building have more control that leads to higher levels of comfort, particularly with Heat Recovery systems in which one unit can be heated while another is being cooled. Also, VRFs are quieter than traditional systems.

According to William Goetzler, writing in the ASHRAE Journal, the energy efficiency of VRFs is often overlooked because the energy savings are difficult to measure.

Rating systems such as EER and SEER measure the energy load for heating or cooling to a certain level in a defined space. They don’t take into account the fact that VRFs usually operate at 40% to 80% of capacity because the units rarely all run at full capacity at the same time.

VRFs integrate well with smart home technologies. This means building operators can provide tenants with increased control, comfort and energy efficiency.

Design considerations

VRFs have design requirements that you will need to follow closely. Make sure your project design can accommodate the manufacturer’s load capacity and limits to pipe length throughout the system.

The footprint of a VRF is a big advantage for project design. The outdoor unit for a VRF is smaller than the chillers used in traditional systems. And a ductless VRF system is ideal for a retrofit in a building that has no ducts and doesn’t need ventilation.

VRF Installation

VRF installation requires special training. Fortunately, many courses are offered in North America. Manufacturers of the systems offer courses, and training is now also available through trade schools.

Let’s Talk Cost

Installation is more costly because VRF equipment tends to be more expensive, and more time and care must be taken to avoid leaks of refrigerant. VRF systems are also costly to operate in regions that experience extreme cold temperatures.

Long term savings outweigh the initial costs in many instances. Energy efficiency reduces energy bills by as much as 40%. Units can be metered so that each unit is responsible for the energy cost, which often results in cost-saving behaviour by users.

Go with the flow

If you install HVAC in a region that doesn’t experience extreme cold, get trained in VRF installation. Your skills will be in high demand. And remember, when your customers choose VRF they want the best for their building. Make sure to include the highest quality fittings for their duct work.